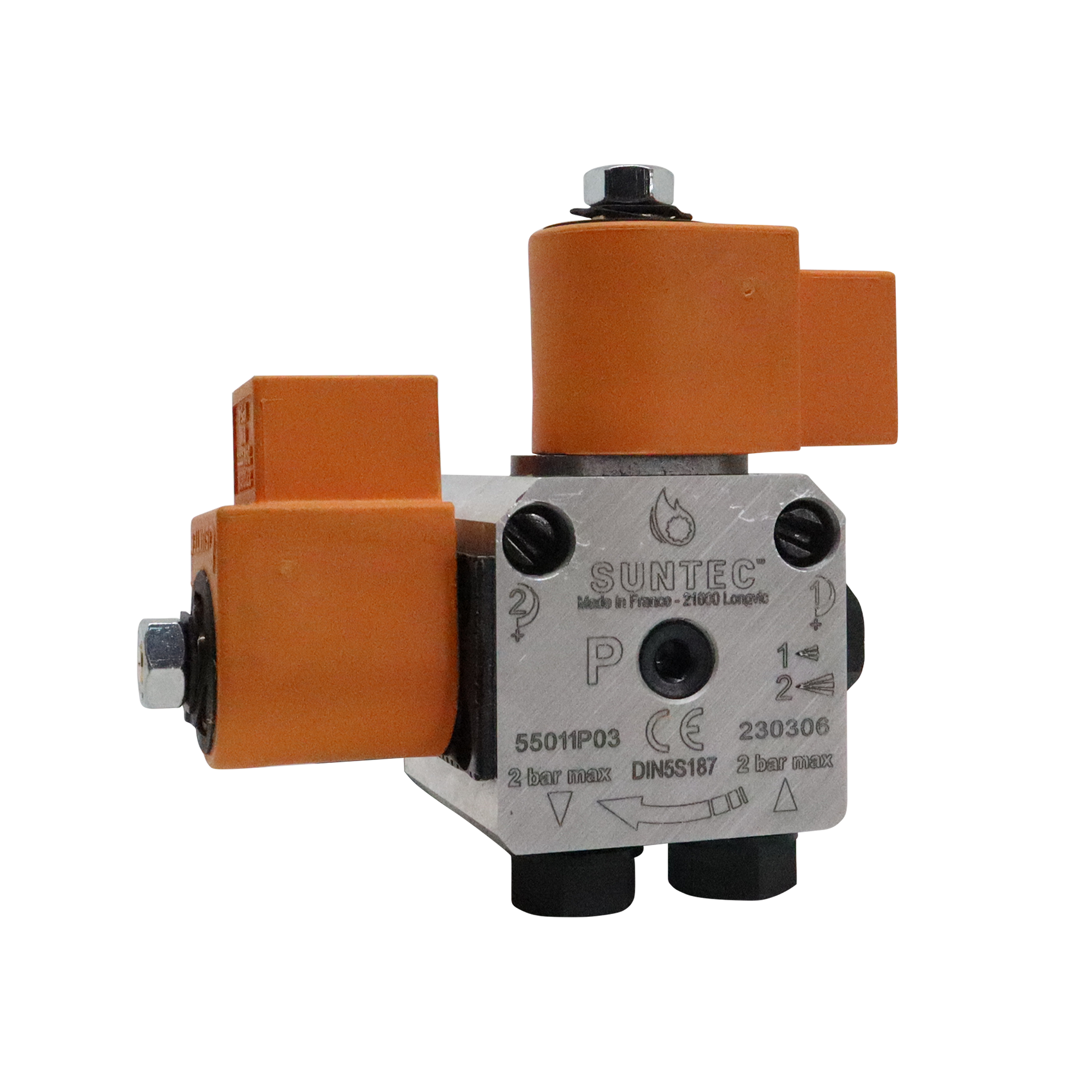

This SC2 pump has a reduced gearset which allows the pump to consume less power. Its modular and compact design allows to fit easily into any environment. It has an integrated solenoid valve that controls the built-in pressure regulator, which allows a speed and independent shutdown and opening. This model is characterized by 2 mode pressure operation and incorporates a blocking solenoid valve with in-line cut-off function. Switching between low and high modes is assured by a 2nd integral solenoid valve.

Compatibility :

The gear set draws oil from the tank through the built-in filter and transfers it to the regulator which allows to regulate the pressure to the nozzle line.

Switching between low and high pressure is assured by a “normally open” by-pass solenoid valve. When this solenoid valve is non-activated, a by-pass channel is open, allowing the normal functioning of the low pressure regulating valve which sets the nozzle pressure.

When this solenoid is activated, the by-pass channel is closed, thus pressure will build up on both sides of the low pressure regulating valve eliminating its effect, and the high pressure regulating valve now determines the nozzle pressure.

Cut-off:

The solenoid valve of this pump is of the “normally closed ” type. This design ensures an extremely fast response, in accordance with the different operating phases of the burner, and does not depend on the motor speed.

When the solenoid is non-activated, and all oil pressurized by the gear set passes through the regulator to the suction or return line, depending upon pipe arrangement.

As soon as the solenoid is activated, oil passes to the nozzle line at the pressure set by the pressure regulating valve.

Bleed: Bleeding in two and one pipe operation is carried out by unscrewing the pressure port.

Installation: Note that configuration is not reversible.

– Two pipe installation:

All oil that does not go through the nozzle line will be dumped through the valve back to the return line.

– One pipe installation:

The excess oil is directly returned to the gear set at the suction point; the suction flow rate is then equal to the flow rate provided by the pump to the nozzle.

Know more :