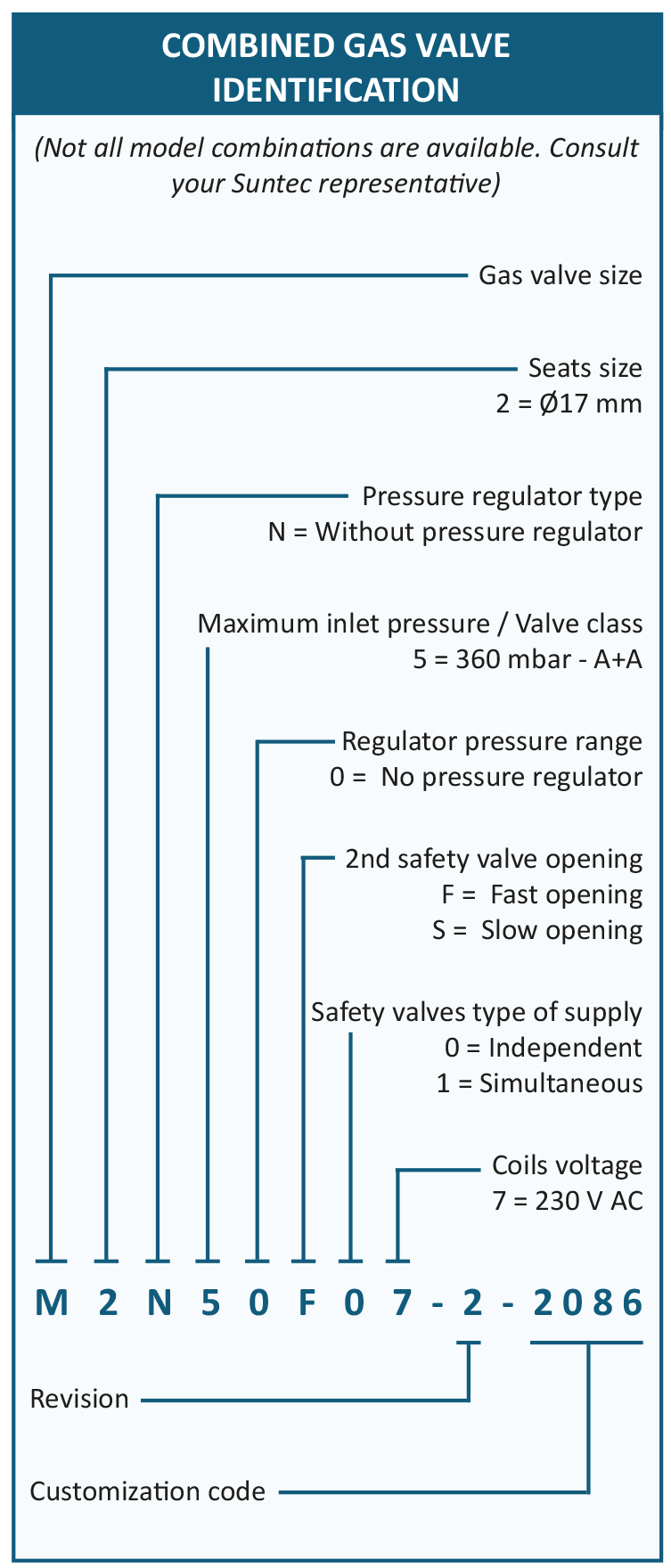

M2N/M3N

The SUNTEC combined gas valves M2N and M3N are design to be adapted on every type of 1-stage gas burner. Made up of 2 class A+A solenoid valves, they allied safety and reliability in every configuration.

Compatibility

The combined gas valves M2N / M3N are available in several version to match every gas burner needs, especially the slow opening which be fully compatible with the requirements of the EN 676 standard (forced draught burner with gas).

M2N and M3N models are CE certified according to EN 161 / EN 126.

Operation

At rest, the 2 solenoid valves are closed: the gas is blocked upstream the gas valve. When the 2 coils are energized, the 2 solenoid valves are opening and let the gas go through the combined gas valve.

Product benefits :

- Aluminium body high quality

- Customable configuration function of your installation: Rp ¾ or Rp ½ flanges, inlet/outlet pressure plug, gas pressure switch…

- Fast close of less than 0,2 seconds when electrical supply is turning off

- Compatibility with all gas types: H2 blend (1st family), natural gas (2nd family), LPG (3rd family)

- Slow opening of EV2 with hydraulic damper (optional) for even more safety

- Compact and interchangeable models as compared with models of market

- Wide operation curve. Important gas flow allowed with high pressure difference

Technical specifications :

| M2N | M3N | |

|---|---|---|

| Maximum operating pressure | 360 mbar | |

| Gas flow at Δp = 100 mbar | 30 Nm3/h | 45 Nm3/h |

| Ambient temperature range | -20°C à +60°C | |

| Weight | M2N**F / M3N**F : 2.3 kg M2N**S / M3N**S : 2.5 kg |

|

| Certification | CE : n°1312CU6361 | |

| Inlet/outlet flanges | DN15 (Rp 1/2 ») DN20 (Rp 3/4 ») |

|

| Pressure switch (optional) | Factory mounted on inlet flange. When suitable configuration, can be side-mounted |

|

| SAFETY VALVE CHARACTERISTICS | ||

| Leakage class | Classe A+A | |

| Opening time (EN 161) | M2N**F : < 0.5s M2N**S : 1s < t < 10s |

|

| Closing time (EN 161) | M2N**F : < 0.2s M2N**S : < 0.2s |

|

| Lifetime (EN 161) | 200 000 cycles | |

| Voltage | 230 V AC, 50/60 Hz | |

| Consumption | 34 VA | |

| IP rating | IP54 (with suitable connector) according to EN 60529 standard. |

|

M2N data sheet

M2N data sheet